Introduction

In the textile industry, ensuring the quality of fabric is critical to maintaining production efficiency and customer satisfaction. Detecting defects such as scratches, irregular textures, ink spots, and color inconsistencies is essential for achieving this goal. This blog explores a successful application of machine vision technology in fabric detection, particularly in a high-speed production environment.

Case Overview

Location: Pakistan

Industry: Textile Manufacturing

A client required an efficient system to detect defects and damages on fabric surfaces moving at high speeds on a production line. The challenge lay in inspecting large-width fabrics accurately and swiftly, without disrupting production.

Solution and Advantages

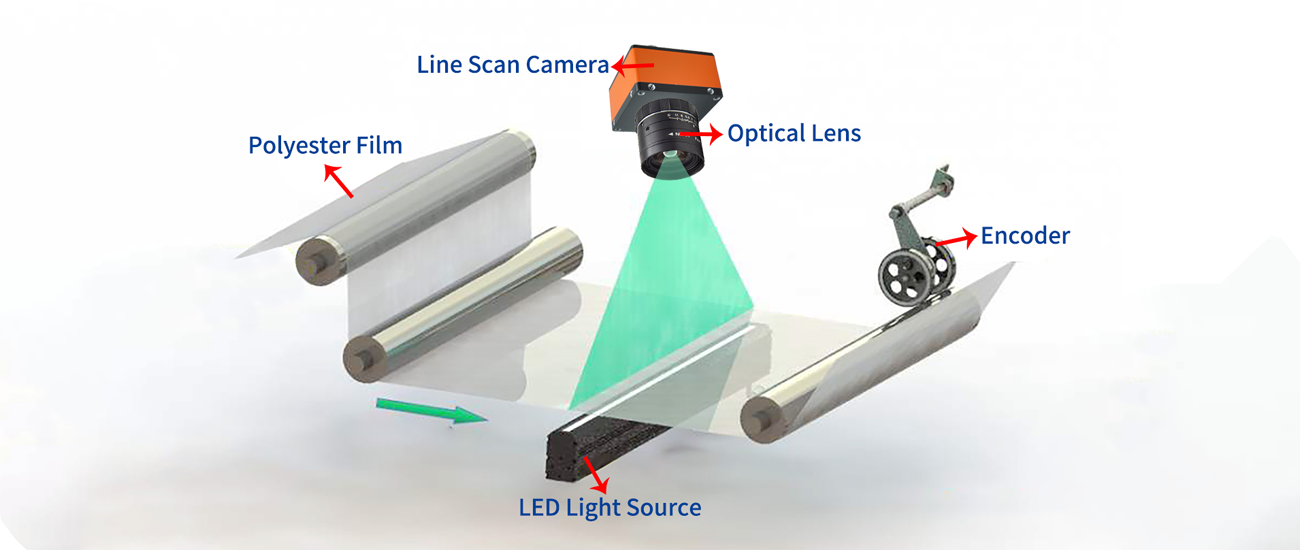

To meet the client’s needs, we proposed a solution combining industrial cameras with a specialized vision light source. Given the high precision and speed required, a line scan camera system was recommended, offering several advantages:

- High Resolution: Equipped with a 4K line scan camera and a 28mm line scan lens, the system delivers sharp and detailed imaging, ensuring the smallest defects are detected.

- Wide Coverage: Custom-designed 2-meter linear light illumination covers the entire width of the fabric, enabling comprehensive inspection in a single scan.

- Enhanced Speed: The setup can efficiently handle the demands of high-speed production, ensuring timely defect detection and minimal downtime.

Technical Highlights

- Camera: Mars4096-L26gm line scan camera.

- Optics: 28mm line scan lens.

- Illumination&Controller: 2-meter linear light source customized for large-width fabric.

- Installation: Configured for both color and monochrome cameras, with working distances of 1.5m for color and 1m for monochrome setups.

Why Choose Machine Vision for Fabric Detection?

- Precision: Line scan cameras excel in detecting minute defects, ensuring quality assurance for end products.

- Efficiency: High-speed operation enables real-time inspection, reducing delays in production.

- Scalability: Customizable setups can cater to varying fabric widths and inspection criteria.

Conclusion

This successful case underscores the transformative potential of machine vision technology in the textile industry. By leveraging advanced camera systems and tailored illumination solutions, manufacturers can enhance product quality while maintaining operational efficiency.

If you're interested in adopting similar solutions for your industry, feel free to contact us.📧 Email: crips.xu@vtocn.com

Let’s redefine quality inspection together!