Application of industrial cameras in food

Industrial cameras are widely used in the fields of food manufacturing and inspection. If some problems cannot be avoided during the production process, it will cause a lot of cost consumption. Using an industrial camera can greatly help you. Let’s take a look at its functions:

Appearance inspection

Industrial cameras can quickly and accurately inspect the appearance of food products. The camera can identify product appearance defects, such as damage, deformation, color difference, etc., and sort out problematic products.

Dimensional measurement

The camera can measure the dimensions of food products through image processing technology. For example, detect bread or biscuits' diameter, length, height, and other parameters.

Color analysis

Industrial cameras can analyze the color of food products. For example, testing the ripeness of fruits and vegetables and judging the quality and consistency of food products.

Label detection

Cameras can detect labels on food products to ensure precise label placement and quality. For example, detect label position, integrity, printing quality, etc.

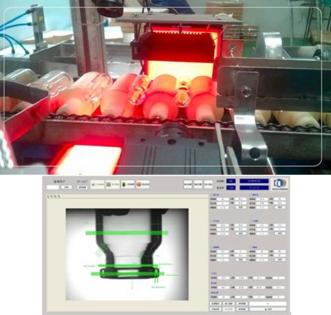

Contaminant detection

Cameras can detect contaminants in food products, such as foreign objects, metal, insect eggs, etc. Through image processing and analysis, problematic products can be sorted to ensure food safety.

Packaging inspection

The camera can inspect food packaging. For example, testing the integrity of sealed packaging, the label fit of cans or bottles, etc.

These applications demonstrate the diverse applications of industrial cameras in food manufacturing and inspection. Through high-resolution, fast image processing and analysis capabilities, industrial cameras can improve food manufacturing processes' automation, quality control, and safety. This allows enterprises to avoid many major cost accidents by spending small costs.